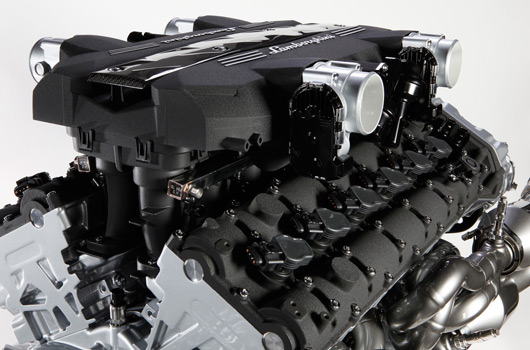

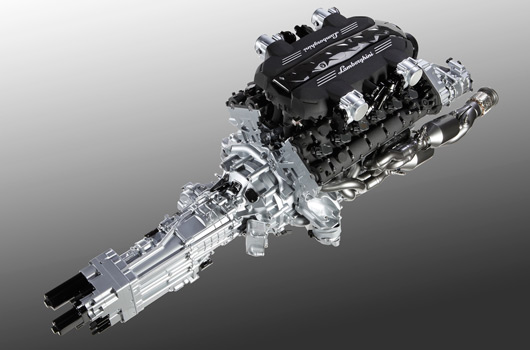

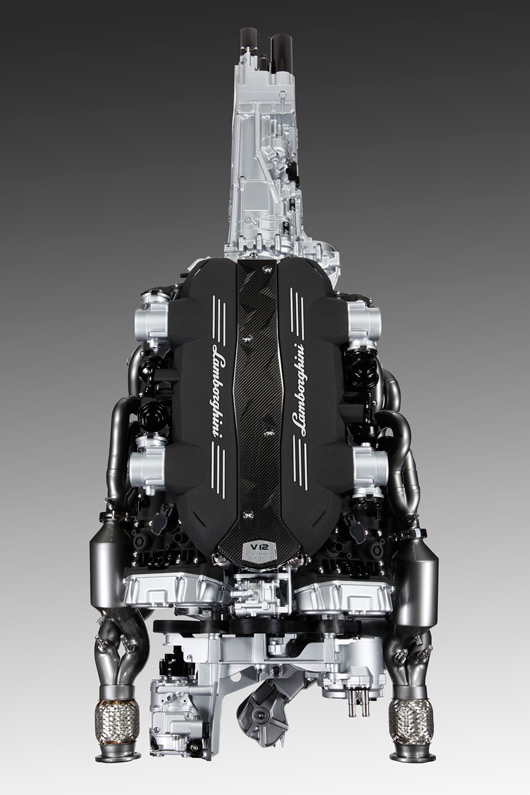

You’re looking at 525kW (700bhp). It’s the new 6.5 litre V12, coupled to an “ISR” automated manual transmisison, that Lamborghini will use to power the upcoming Aventador.

Stephan Winkelmann, President and CEO of Lamborghini is over the moon with his new powertrain, “With this new V12, we are heralding a technological leap that encompasses all areas of the company and our future model lineup. With a unique package of innovations, Lamborghini will redefine the future of the super sports car. This 700 hp engine, together with an all-new concept gearbox, will be the strong heart of the Murciélago successor next year.”

The high-revving V12 achieves its peak power at 8250rpm, while all 690Nm of torque is on offer at 5000rpm. Lamborghini say four throttle openings and a highly complex intake system gives the engine a well-rounded torque curve, with get-up-and-go on tap right through the rev range. Use of advanced materials such as aluminium-silicon has allowed Lamborghini to keep the weight of this big lump to 235kg.

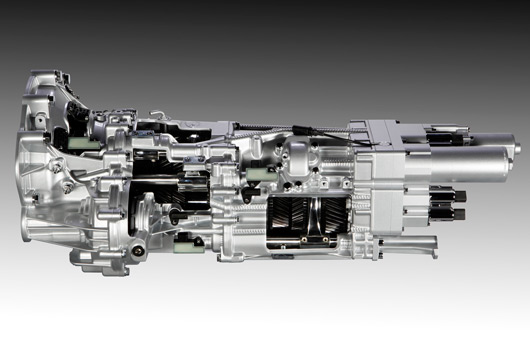

Also featuring in the new powertrain is a 7-speed Independent Shifting Rod (ISR) transmission. Apparently it is the “world’s most emotional gear shift.” It tips the scales at 79kg and can shift cogs up to 40% quicker than the Murci’s old e-gear setup.

More pics and press guff after the break. There are two press releases and, if you have the time, the long version provides some good detail.

(The short version)

Another milestone in the history of Lamborghini:

The new twelve-cylinder and the new ISR transmission – Innovative technologies for a unique powertrain

Sant’Agata Bolognese, November 15, 2010. Automobili Lamborghini is embarking on a highly innovative chapter in the company’s history with an all new V12 power plant and a new, unique high performing transmission – the twelve-cylinder with 6.5 liter displacement, output of 525 kW (700 hp) and maximum torque of 690 Newton meters was developed with state-of-the-art technology from a clean sheet of paper. The result is a synthesis of breathtaking performance, high-revving exhilaration, low weight and moderate gas emissions. The perfect complement is a completely new transmission concept for super sports cars: the “Lamborghini ISR†automated manual gearbox combines minimal shift times and everyday usability with low weight and dimensions to guarantee that emotional sensation from gearshifts, which customers expect from a super sports car at the very top of the premier league. The new powertrain will enter production early 2011.

The legend of Lamborghini strongly relies on its extraordinary, unique V12 engines.“This new power unit is not only the crowning glory of our product range, it is also part of our enormous investment in the future of the Lamborghini brand,†says Stephan Winkelmann, President and CEO of Automobili Lamborghini. “With this new V12, we are heralding a technological leap that encompasses all areas of the company and our future model lineup. With a unique package of innovations, Lamborghini will redefine the future of the super sports car. This 700 hp engine, together with an all-new concept gearbox, will be the strong heart of the Murciélago successor next year.â€

Top performance, low weight

Twelve-cylinder engines are fundamental to the legendary Lamborghini brand – in the past and in the future. The very first model by Ferruccio Lamborghini, the 350 GT, first appeared on the market in 1964 with a twelve cylinder power unit that was extremely innovative for its day. Miura, Espada, Countach, Diablo and, most recently, Murciélago are just a few of the super sports car to have been built in Sant’Agata. All of them were and will be driven by V12 engines – and all have long since taken their place in history as automotive legends.

The next milestone in this glorious history now awaits – Lamborghini’s research and development engineers started with a clean sheet of paper to create an all-new high-performance power plant. The resulting package is extremely powerful and high-revving, yet compact. At 235 kilograms, it is also extremely lightweight – with every single kilo of engine weight representing around three hp of maximum output.

High-revving joy, stunning sound

Even in the world of super sports cars, 515 kW (700 hp) at 8,250 rpm sets a new benchmark. Maximum torque stands at 690 Newton meters and is available at 5,500 rpm. The extremely well-rounded torque curve, beefy pulling power in every situation, incredibly spontaneous responsiveness and, not least, the finely modulated but always highly emotional acoustics make this engine a stunning power unit of the very highest order. Not only was it developed entirely in-house by Lamborghini, it is also manufactured from start to finish at company headquarters in Sant’Agata Bolognese. Highly qualified specialists assemble the engines by hand, with every single one then tested extensively and finely calibrated on an engine test bed.

This exceptional athlete derives its power from a whole package of innovative technologies. For optimum weight, the crankcase and the four-valve cylinder heads are made from aluminum-silicon alloy. The short-stroke layout ensures exceptional high-revving performance and very low internal friction. A lengthy process of fine tuning perfected the thermal management system for the highperformance power unit, as well as the oil circulation system with dry-sump lubrication. The intake system with four individual throttle valves is highly complex – an extremely well-rounded torque curve and outstanding pulling power across the rev range the reward. The exhaust system delivers the lowest emission levels, as well as that unmistakable, spine-tingling Lamborghini sound – from a moderate rumble when cruising through the city at low revs to the howling crescendo of gears at their limits.

Innovative transmission for maximum performance

Engineers working under the sign of the bull have come up with an ingenious mate for the new twelve-cylinder engine in the shape of the Lamborghini ISR transmission. Overall, this is a drive unit that is absolutely unique in the competitive world of super sports cars. The development target was clearly formulated – to create the world’s most emotional gearshift feel. This innovative manual gearbox combines extremely fast shift times – almost 50 percent shorter than with a dual-clutch transmission – with the benefits of manual shifting when it comes to low weight and compact dimensions, both always crucial for a super sports car. The low shift times are enabled through the transmission’s particular design, known as ISR (Independent Shifting Rod). Instead of taking place in series, as with a conventional gearbox, shifting can occur virtually in parallel. While one shifting rod is moving out of one gear, the second shifting rod can already engage the next. Moreover, the transmission weighs only 79 kilograms – a distinct benefit, even against comparable DSG transmissions, which are considerably heavier.

(The long version)

Another milestone in the history of Lamborghini:

The new twelve-cylinder and the new ISR transmission – Innovative technologies for a unique powertrain

Sant’Agata Bolognese, November 15, 2010. Automobili Lamborghini is embarking on a highly innovative chapter in the company’s history with an allnew V12 power plant and a new, unique high performing seven speed transmission: The twelve-cylinder with 6.5 liters displacement, output of 525 kW (700 hp) and maximum torque of 690 Newton meters was developed with state-of-the-art technology from a white sheet of paper. The result is a synthesis of breathtaking performance, high-revving exhilaration, low weight and moderate gas emissions. The perfect complement is a completely new transmission concept for super sports cars: The “Lamborghini ISR†automated manual gearbox combines minimal shift times and everyday convenience with low weight and dimensions to guarantee the emotional gearshift that customers expect from a super sports car at the very top of the premier league. The new powertrain will enter production early 2011.

The legend of Lamborghini strongly relies on its extraordinary, unique V12 engines.“This new power unit is not only the crowning glory of our product lineup, it is also part of our enormous investment in the future of the Lamborghini brand,†says Stephan Winkelmann, President and CEO of Automobili Lamborghini. “With this new V12, we are heralding a technological leap that encompasses all areas of the company and our future model range. With a unique package of innovations, Lamborghini will redefine the future of the super sports car. This 700 hp engine, together with an all-new concept gearbox, will be at the heart of the Murciélago successor next year.â€

The new V12 power unit – The heart of Lamborghini

The twelve-cylinder is the king of the engine world and the true heart of the Lamborghini brand. The very first model created by Feruccio Lamborghini, the 350 GT, made its appearance in 1964 featuring a twelvecylinder engine that was incredibly innovative for its day. 3.5 liter displacement and 320 hp were the vital statistics back then – they formed the basis for ongoing increases and further development over the decades that followed. Miura, Espada, Countach, Diablo and, finally, Murciélago are just a few of the super sports cars born in Sant’Agata. All of them were, and will continue to be, driven by V12 engines – and all have long since risen to the status of automotive legend.

Now the next milestone in this glorious history appears – engineers in the Lamborghini R&D Department have developed a completely new highperformance power unit. That it would be another twelve-cylinder was never in doubt – and not only because of the special magic conjured up by the number twelve. The only real choice for Lamborghini is a high-revving naturally aspirated engine – the deeply reflexive and exceptionally powerful reaction of the automobile to the tiniest movement of the driver’s right foot is, of course, a key part of the whole fascination inspired by a super sports car. Ten cylinders are ideal in the displacement class around the five liter mark, as evidenced by the highly acclaimed Gallardo engine. For the 6.5 liter displacement targeted in this case, the perfect number is twelve. A lower number of cylinders would result in larger and heavier pistons and con-rods, which would have a negative impact on the engine’s high-revving characteristics.

Starting with a clean sheet of paper

The specification for the development of the new twelve-cylinder, known internally as the L539, was written quickly – yet was highly demanding in its formulation. Naturally, it had to deliver more power and torque than its predecessor in the Murciélago, but it should also be smaller and lighter and enable a lower center of gravity. At the end of the day, low weight is just as important to the performance of a super sports car as high power output. Fuel consumption and gas emissions should also be reduced significantly.

So the R&D team started with a clean sheet of paper – metaphorically speaking, of course. Design and development in Sant’Agata is conducted using state-of-the-art systems and equipment. The outcome is a V12 with a classic cylinder bank angle of 60 degrees, and thus an amazingly compact power package – the power unit measures only 665 millimeters from top to bottom, including the intake system. Its width, including the exhaust manifold, is only 848 millimeters, while its length is a mere 784 millimeters. Its weight of 235 kilograms is also respectably low – each kilogram of engine weight corresponds to 3.0 HP maximum output.

Optimized for high revving and low weight

The crankcase on the new power plant is made from an aluminum-silicon alloy and has an open-deck construction with steel cylinder liners. Displacement is 6,498 cm3 and cylinder spacing 103.5 millimeters, while bore diameter measures 95 millimeters and stroke 76.4 millimeters. The short-stroke layout is especially good for high-revving characteristics and for low internal friction. Particular attention was also paid to the bearings for the forged and nitride-hardened crankshaft, which weighs in at 24.6 kilograms.

The two four-valve cylinder heads are likewise made from sand-cast aluminum-silicon alloy, each weighing a very light 21 kilograms. The twelve pistons and con-rods are, respectively, in forged alloy and steel. The maximum piston speed at 8,250 rpm is only 21 meters per second, which is considerably less than for the Murciélago’s previous power unit. The combustion chambers were carefully engineered to achieve optimum tumble and combustion of the fuel/air mixture. At 11.8:1, the compression ratio is extremely high. Inlet and outlet valve timing is electronically controlled.

Sophisticated thermal management, optimized oil circulation

The thermal management of this high-performance power unit was perfected with extensive detail engineering. Two switchable water circuits in the engine ensure very rapid warm-up, which minimizes friction and quickly brings the catalytic converters up to operating temperature, thus benefiting fuel consumption and emissions. The external water coolers are switched into the circuit only as required.

Absolute engine health, even under extreme racetrack conditions with high lateral acceleration, is guaranteed by oil circulation using a dry sump system. A total of eight scavenger pumps suck oil out of the lower bedplate fastened to the crankcase. Pressure and scavenging losses are thus reduced by around 50 percent. A high-pressure oil pump maintains lubrication, while an oil/water cooler and an oil/air radiator constantly keep temperatures within range even under extremely high load. A further benefit of this form of dry sump lubrication is the very low mounting position of the engine within the sports car. The new engine is mounted 60 millimeters lower than the V12 in the Murciélago – with the associated benefits in respect of center of gravity and lateral dynamics.

From the outside, the V12 is dominated by its intake system – which incorporates four individual throttle valves. Life inside the black housing is also extremely complex – the optimum intake path for any given load and engine speed is facilitated by two flaps, several channels and one bypass. The payback is an extremely well-rounded torque curve and refined pulling power throughout the rev range.

Mighty orchestra for twelve voices

The exhaust system, too, was afforded the undivided attention of Lamborghini’s engineers – the lowest possible gas emissions was just as important a target as the unmistakable, spine-tingling Lamborghini sound. The hydro-formed and thermally insulated three-into-one system incorporates four pre-catalytic converters close to the engine and two main catalytic converters shortly before the muffler. The casing incorporates two separate mufflers – one low-volume, one high-volume. Regulated by valves controlled via the engine management, they handle all the elements of the big twelve-cylinder symphony – from a moderate rumble when rolling through the city at low revs to the screaming crescendo of maxed-out gear shifts.

Electronics devised entirely by Lamborghini

Another highlight is the electronic engine management, which was developed in its entirety by engineers at Lamborghini. The system consists of the main ECU, a secondary “smart actuators†and two additional black boxes that function as “smart sensorsâ€. Because speed is everything for an engine like this, some ECU control and connection functions are handled by the smart actuators, making the ECU faster. The two smart sensors are constantly monitoring combustion in real time – each ignition in every cylinder. The spark plugs – each is powered by an individual ignition coil – function as “sensorsâ€; the two auxiliary control units monitor the power signal after every ignition and can immediately identify irregularities in the combustion process through ionization phenomena. This data is used to continually optimize engine management, benefiting both performance and fuel consumption.

High performance in every dimension

All these technical highlights come together to create a high-performance power unit like no other. The maximum output of 515 kW (700 hp) at 8,250 rpm is an impressive statement in itself. The maximum torque is 690 Newton meters and is available at 5,500 r/min. The extremely generous torque curve, meaty pulling power in every situation, extremely reflexive responses and, not least, the finely modulated but always highly emotional acoustics make the L539 a stunning power unit for a super sports car of the highest order. And not only was the L539 developed entirely in-house at Lamborghini, it is also built from start to finish at company headquarters in Sant’Agata Bolognese. Highly qualified specialists assemble the engines by hand, with every single unit undergoing an extensive final testing and detailed calibration program on an engine test bed.

The new Lamborghini ISR transmission (ISR: Independent Shifting Rods) – Innovative servo-actuated mechanical gearbox for maximum Performance

However, it is not the engine alone that defines the character and driving characteristics of a super sports car. Another key element is the transmission. The demands are clear – the ratios must be perfectly arrayed and enable optimum power delivery from the engine. For maximum vehicle performance, shift times should be less than the blink of an eye. Operation must be clear and straightforward, via two ergonomic shift paddles behind the steering wheel. The characteristics of the transmission must be in line with the wishes of the driver at any given point – from smooth city cruising through to tough action on the racetrack. And, not least, Lamborghini customers expect an emotional shift feeling that ensures the sports car’s reactions can always be felt and understood. Thus, the development objective was clearly formulated in this respect, too – create the world’s most emotional gear shift.

For all these reasons, the engineers in the R&D Department opted for a robotized gearbox as the “companion†of the new V12 power unit – however, in a very special iteration: the Lamborghini ISR transmission. This robotized gearbox combines extremely fast shift times, almost 50% less than dual-clutch transmission with the benefits of a manual transmission in terms of weight and compact dimensions – both always critical for super sports cars.

Unique engineering for super sports cars

The new unit is laid out as a two-shaft transmission with seven forward gears and one reverse. For especially high durability, the synchronizing rings are made from carbon-fiber – a material with which Lamborghini has enormous experience. The short shift times are facilitated by the special design of the transmission, known as ISR – Independent Shifting Rod. To summarize the principle – in a conventional manual gearbox, be it automated or fully manual, the gear wheels for, say, second and third gears are located side by side. When the driver wants to shift gear, the shifting sleeve with synchronizer unit is moved along the shifting rod from second gear through neutral to third gear. This requires twice the distance and twice the time – second gear has to be disengaged before third gear can be engaged.

Short distances, fast shift times

This process is significantly shortened in the Lamborghini ISR transmission – the gear wheels from the second and third gears are separate from each other and the shifting sleeves are actuated by independent shifting rods. Now the shifting process can run virtually in parallel – while one shifting rod is disengaging one gear, the second shifting rod can already engage the next gear. Because these movements partially overlap and the mechanical distances are considerably shorter, this facilitates a significant saving in shift time. Overall, the Lamborghini ISR transmission shifts around 40 percent faster than the e.gear transmission in the Gallardo. And that is already one of the world’s fastest automated manual gearboxes.

Compact construction, low weight

The new transmission has four of these independent shifting rods, with sensors constantly monitoring their exact positions. They are operated via hydraulic actuators, with an extremely high system pressure of 60 bar ensuring the necessary operating speed. The system incorporates a total of seven hydraulic valves, with pressure supplied by an electric pump. The double-plate clutch is also hydraulically actuated. All system components are contained within one casing. The total weight of the transmission is only 70 kilograms – a distinct advantage, especially compared with the significantly heavier dual-clutch transmissions from the same category

Three operating modes for all situations

Lamborghini drivers can choose between three operating modes – the Strada mode offers highly comfort-oriented shifting, with fully-automatic also an option. The Sport mode has a dynamic set-up in terms of shifting points and times, while the Corsa mode delivers the maximum shift strategy for race track driving. This mode also includes Launch Control, the automatic function for maximum acceleration from a standing start.

With the Lamborghini ISR transmission, engineers working under the sign of the bull have devised an ingenious mate for the new twelve-cylinder power unit. Their work has created an overall powertrain that is absolutely unique in the world of super sports cars.

Integrated electronic control system

The excellent performances are possible only by a fast communication architecture through the several powertrain ECU’s and considering the powertrain as ONE-system (un unico sistema) in the car.

The fully electronic controlled coupling device for the front wheels (the ‘old’ viscous coupling) is another key point of the powertrain: it is able to continuously distribute the right torque to the front wheels for always attaining the best performance aspired to by the driver. The torque distribution to the front wheels can vary continuously from 0% to 60% of the total torque available.

The history – The twelve-cylinder at the heart of the brand with the bull

Lamborghini V12 – that means a long and glorious story. According to the history books, Ferruccio Lamborghini established a car company in the early sixties because he wanted to better the products on offer at the time from the competition, with the best possible technology and quality. The prototype for all later Lamborghini super sports cars was the 350 GTV study presented at the Turin Motor Show in 1963. It featured an all-new aluminum twelve-cylinder developed from scratch by engine designer Giotto Bizzarini and boasted performance figures that were nothing short of breathtaking by the standards of the time. The 12-cylinder V-engine with 60 degree cylinder bank angle, four overhead camshafts (at a time when single camshafts were still the norm), a six bbl carburetor and dry sump lubrication, generated 360 hp at 8,000 rpm from a displacement of 3,497 cm3 that would take the concept car to a top speed of 280 km/h. The 350 GT series production version with conventional lubrication, launched the following year, produced 320 hp at 7,000 rpm from a displacement of 3,464 cm3.

It was exactly this engine that captured the imagination of show-goers at the 1966 Geneva Auto Salon in the Lamborghini Miura. Although its main features were already familiar from the 400 GT, this time the four-liter 60° twelve-cylinder was mounted transversely behind the cockpit, with transmission and differential in a single unit fixed directly to the frame. The 320 hp made the series production Miura that followed the fastest production car of its time with a stated top speed of more than 280 km/h – and, with that, the first true super sports car. This engine was further developed over the years, with several iterations featuring in the Miura S (370 hp at 7,000 rpm, 285 km/h) and Miura SV (385 hp, 300 km/h). In the Miura Jota, a one-off made for racing, the V12 generated 440 hp at 8,500 rpm. However, applications for the four-liter were not limited to the midengine Miura. In the front-engine Islero, introduced in 1968, and in the 400 GT Jarama, it produced 350 hp, while in the futuristic Espada the figure was 325 hp (later also 350 hp). In 1974, the Espada also saw an automatic transmission offered for the first time.

The generational shift from the Miura to the new LP400 Countach took place in the early seventies. 1971 brought the prototype with a breathtaking, edgy form, the genes of which would ultimately re-emerge forty years later in present-day Lamborghini super sports cars. Marcello Gandini’s design was a fitting outfit for a five-liter version of the V12. However, this engine was dropped from the series production model in 1973 in favor of a further evolution of the four-liter unit. In the 1973 Countach – still without the “wing†or spoiler of the eighties – it was longitudinally mounted behind the driver, where it generated 375 hp at an impressive 8,000 rpm and reached a top speed of 300 km/h. The years that followed saw the Countach engine undergo a series of evolutionary developments, although still based on the familiar cornerstones of the first V12 unit. It was in 1985 that the Countach Quattrovalvole took displacement over the five-liter mark for the first time (5,167 cm3) and – as the name implies – featured a four-valve cylinder head. Output was an impressive 455 hp at 7,000 rpm.

In 1986, the five-liter V12 was presented with a completely new application – the Lamborghini LM002 may also have had the 450 hp engine mounted up front, but the 2.7 ton automobile was the first and only SUV produced by the brand, a four-door all-terrain vehicle. The late eighties saw the amazingly long career of the Countach near its end with the Countach Anniversario. The Diablo followed as its rightful heir, clad in a distinctly nineties outfit. By 1990, the V12 had grown to almost six liters and produced 492 hp. One year later, the Diablo VT was the brand’s first fourwheel drive sports car. Over the next few years, output grew steadily to 520 hp (1993 Diablo SE). The Diablo GT with 575 hp and the radical GTR with 590 hp both appeared in 1999. The Diablo 6.0 was the first model to feature the V12 with displacement expanded to six liters, its output ultimately reaching 550 hp.

The Murciélago was launched in 2001 as the first Lamborghini of the new era. It boasted a new 6.2 liter alloy V12 with a crankshaft running on seven bearings and dry-sump lubrication. It generated 580 hp at 7,500 rpm and took the super sports car weighing just 1,650 kilograms to a top speed of 330 km/h. The maximum torque of 650 Nm was reached at just 5,400 rpm. At the 2006 Geneva Motor Show, Lamborghini unveiled the Murciélago LP 640, which produces 640 hp from the V12 unit that had been expanded to 6,496 cm3. In the strictly limited Lamborghini Reventón, the twelve-cylinder that is the very heart of the brand generated 650 hp. The grand finale came with the Murciélago LP 670-4 Superveloce with its 670 hp. However, 2011 will mark the start of a new chapter in this glorious story…

6 replies on “Lamborghini reveals new 6.5 litre V12”

holy crap thats hot!

I am interested to find out more about this ISR. Will it shift better than the LP640 which is horrible to drive around town.

[…] we brought you news and pics of Lamborghini’s new 6.5 litre V12. Today, via Lamborghini, we bring you video of the beast in action. To be honest, this clip is a […]

[…] LP700-4 (aka Aventador). We already know the Murcielago replacement will be powered by a 700PS 6.5 litre V12. And we also know the same car will be fitted with a trick 7-speed gearbox featuring new […]

[…] in March, Lamborghini has been drip feeding information. So far we’ve had confirmation of the 700hp V12 engine that will power the Aventador. Last week Lamborghini also revealed details about the suspension […]

[…] is aggressive, frightening and stylish all at the same time. When you start thinking of its 700hp 6.5 litre V12 and the F1-inspired suspension you start to get, well, a wee bit excited at just how ballistic this […]